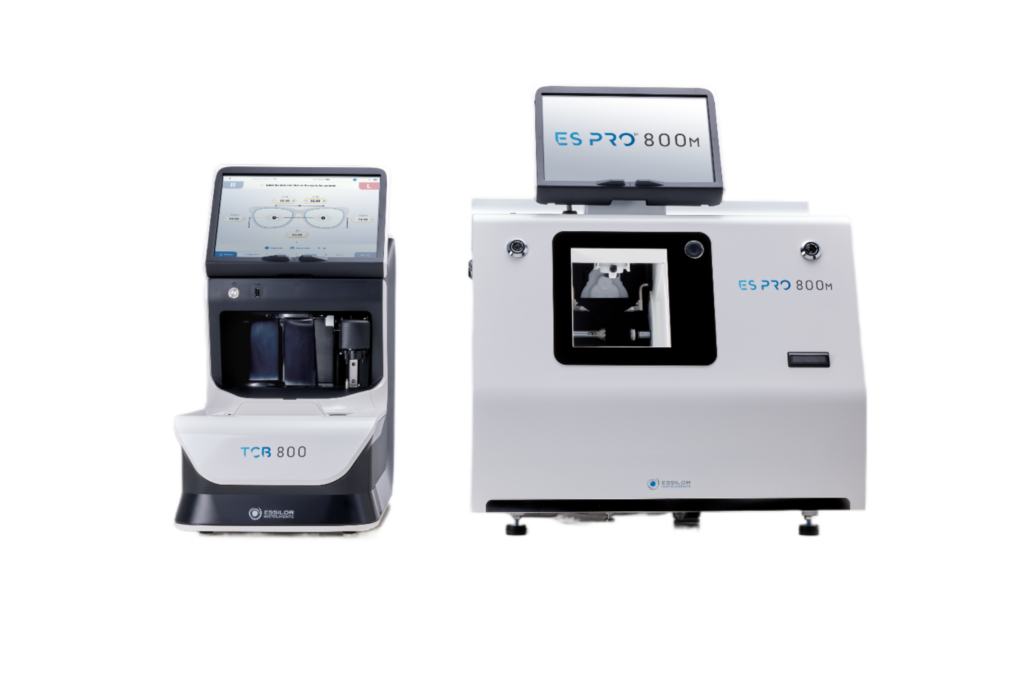

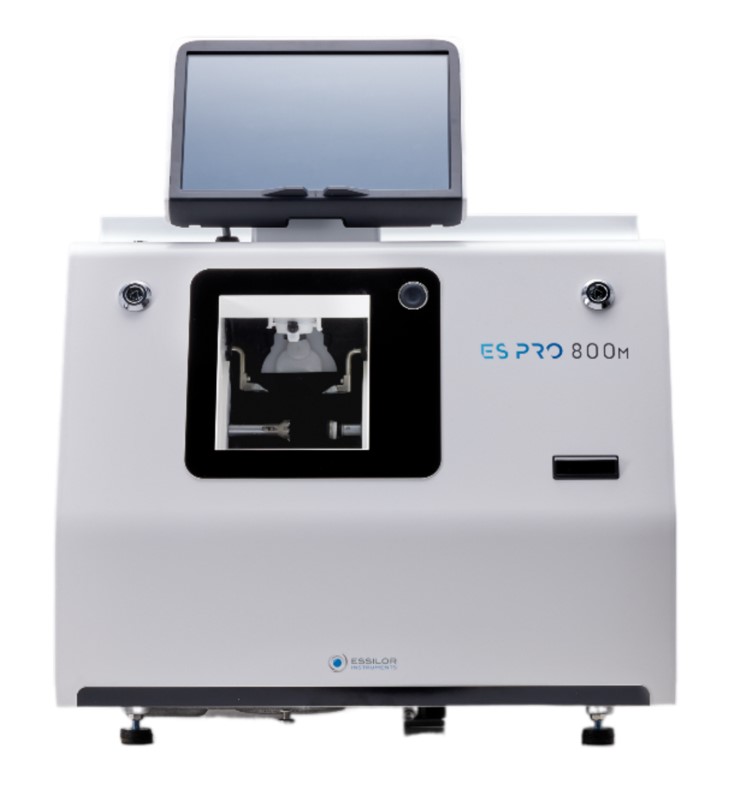

ES PRO™ 800M Edger for High-Volume Labs

Supercharge your edging system

ES PRO 800M is a cutting-edge in-lab finishing solution to boost your productivity and expand your lab’s capabilities. It combines precision, versatility, robustness and speed*, providing a comprehensive solution and greater capabilities.

- Accelerate your Productivity

- Edging time reduced by up to 41%

- Milling time reduced by up to 57%

- On average 25% faster vs PRO-E 600/700

- Streamline integration and bolster connectivity

- Enjoy quick installation and ergonomic experience

- Achieve top-notch precision

- Aesthetic and robust mountings

- Edging precision built on state-of-the-art innovations

- Avoid axis-deviation risks and prioritize safe mounting

- Offers a responsible edging approach through its milling function

- Water consumption can be reduced by as much as 66%.

- Exceed customer expectations

- Enhance your lab’s capabilities and maximize your offerings

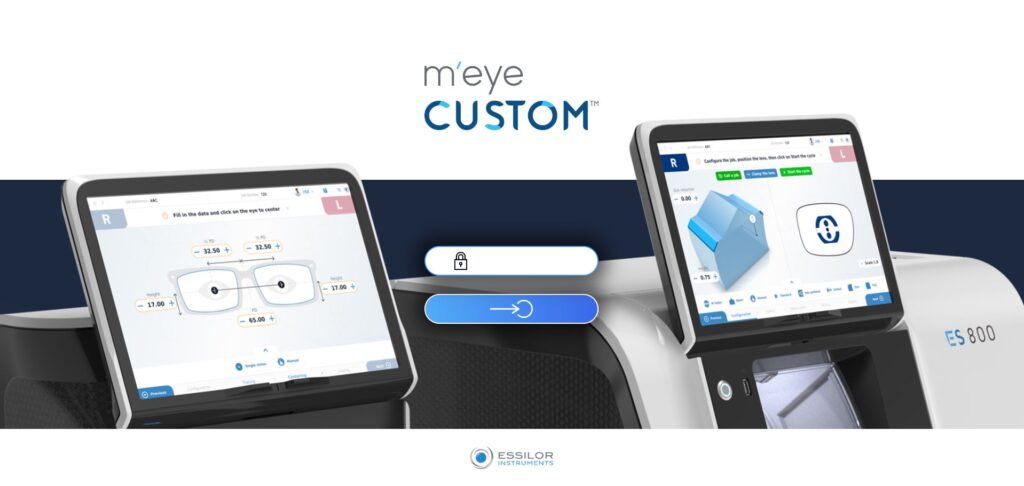

- Half Jacket frames, thick lens management, m’eye CUSTOM web app

Manufactured by Essilor | CE- and UL-certified

Request PricingAdd to cart

DRIVE YOUR PRODUCTIVITY

ES PRO™ 800M is a cutting-edge in-lab finishing solution to boost your productivity and expand your lab’s capabilities. It combines precision, versatility, robustness and speed*, providing a comprehensive solution and greater capabilities.

Edging Time Reduced by up to 41%¹

- Thanks to the SuperVeloce™ roughing cycle, the total process time to edge a lens has been reduced to up to less than 1 minute or 27 jobs per hour.

- A new set of wheels provides better grinding power and allows for faster and more efficient edging.

The ES PRO 800M improvement is on average 25% faster vs. PRO-E™ 600/700².

Milling Time Reduced by up to 57%¹

- The ES PRO 800M milling tool’s lifespan is multiplied by six, regardless of the lens material¹.

- The combination of a robust and sturdy machine design along with specific shapes and dimensions of the cutting tool enables faster and more efficient milling, drilling and grooving.

1. As per Internal PQV study performed in Jan. 2024. ES PRO™ 800M / 700M compared with ES™ 800M and ES™ 700M, for rimmed frames with no chamfering/polishing function.

2. As per Internal PQV study performed in Jan. 2024. ES PRO™ 800M / 700M compared with PRO E™ 700 / 600, for rimmed frames with no chamfering/polishing function.

3. Subject to certain conditions such as the lens type, lens finishing and edging cycle.

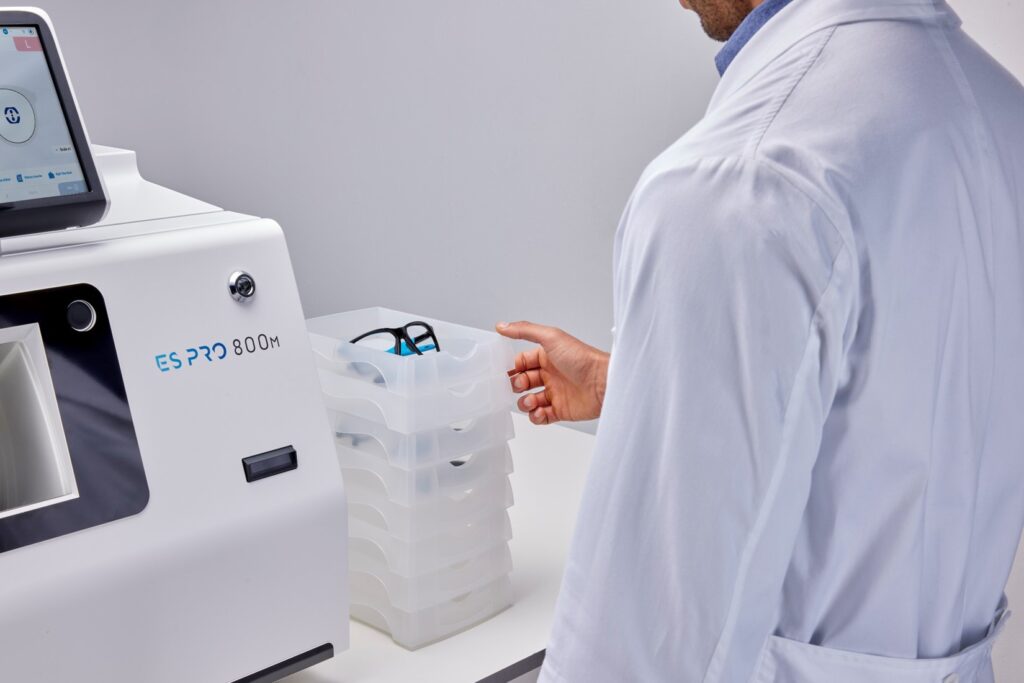

STREAMLINE INTEGRATION AND BOLSTER CONNECTIVITY

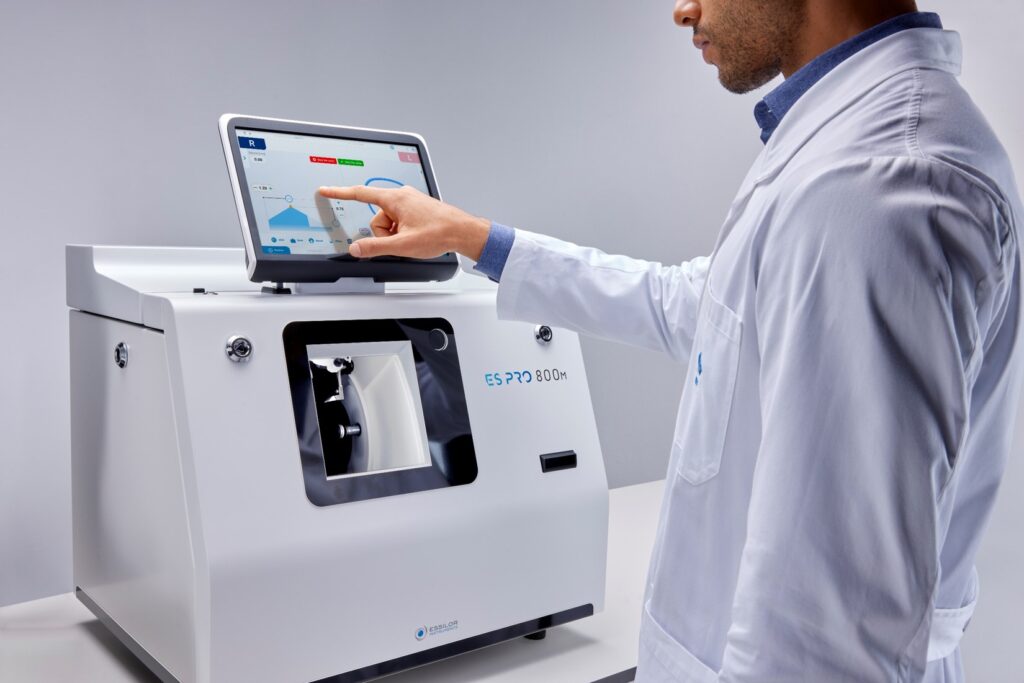

Enjoy quick installation and ergonomic experience

ES PRO 800M fits into any lab with ease. This robust and compact tabletop edger requires no vacuum or compressed air, which means no extra investment.

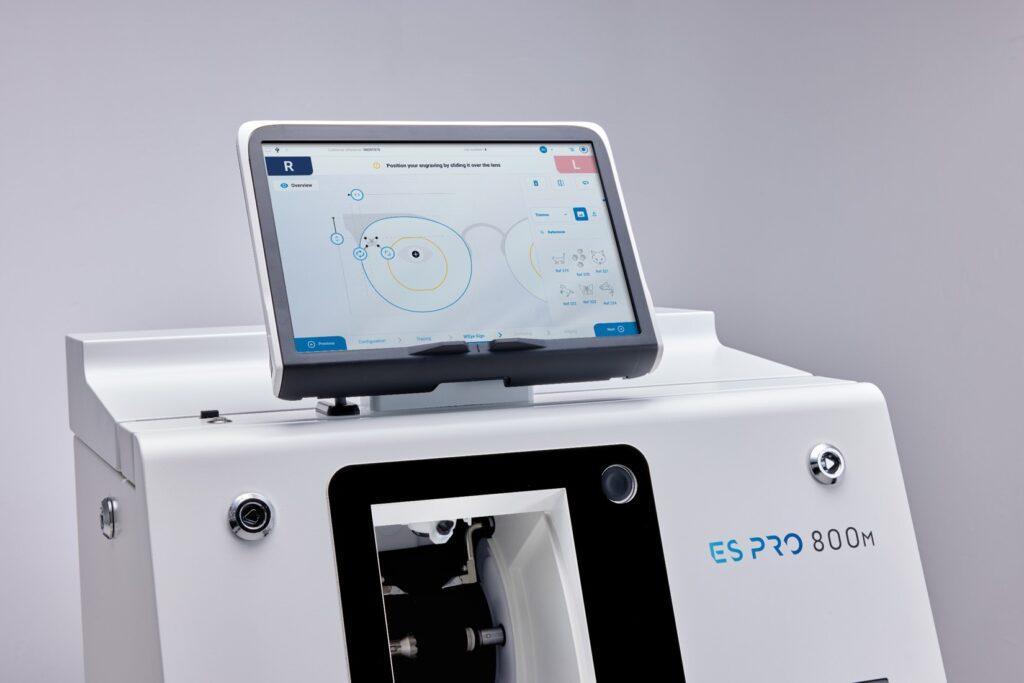

The tiltable 12-inch multi-touch screen offers a comfortable heads-up navigation experience with 3D views that showcase every detail.

ACHIEVE TOP-NOTCH PRECISION

Aesthetic and robust mountings

Fit 4 Frame 2.0 technology enables the realization of a diverse array of bevels to accommodate various frame profiles, including both step and step back bevels. It ensures the ideal lens fit, without any compromise on aesthetics, for all mountings and finishes.

Edging precision built on state-of-the-art innovations

Real-Time Control of Cutting Forces – Take real-time control of the wheel’s cutting force through its SuperVeloce cycle function for optimized precision.

Full High-Curve Technology – Take advantage of a self-adjusting process that simplifies your mountings up to base 10.

Avoid axis-deviation risks and prioritize safe mounting with ES PRO 800M

Real-time control of cutting forces

- The roughing cycle automatically adapts to the curves of lenses up to base 10, avoiding risks of breakage.

- Bevel placement and shelf depth are optimized for safe mounting without undue stress on the lens.

Comprehensive axis control

- ES PRO 800M cuts all lenses¹, including slippery hydrophobic lenses, with fine-tuned precision, thanks to its hybrid milling and grinding technology².

ES PRO 800M offers a responsible edging approach through its milling function.

- Dry-cut technology reduces water consumption, lens waste, and unwanted odors generated during the milling process.

- This produces fewer dust particles that would otherwise end up in the recycling tank or drain depending on the installation of the workshop; thereby reducing lens swarf.

Water consumption can be reduced by as much as 66%.

1. All lens materials except glass.

2. Essilor Instruments places the utmost importance on developing innovations and protecting them with the appropriate patent filings.

3. As per Internal PQV study performed in Jan. 2024. ES PRO™ 800M / 700M milling cycle compared to 1 star cycle for rimmed frames with no chamfering/polishing function.

Click on the image to enlarge:

EssilorLuxottica proudly presents m’eye DIAMOND™ — a revolutionary feature that turns prescription lenses into dazzling, personalized creations. Available exclusively through the ES™ 800 and ES PRO™ 800M edgers combined with the TCB™ 800, it allows eye care professionals to offer a truly elevated eyewear experience. With m’eye DIAMOND, wearers can choose from a variety of crystal pavé designs in different patterns, sizes, and colors. The mix-and-match system lets users personalize their eyewear with shimmering crystal colors. Each pair becomes a reflection of individual style and creativity.

EssilorLuxottica proudly presents m’eye DIAMOND™ — a revolutionary feature that turns prescription lenses into dazzling, personalized creations. Available exclusively through the ES™ 800 and ES PRO™ 800M edgers combined with the TCB™ 800, it allows eye care professionals to offer a truly elevated eyewear experience. With m’eye DIAMOND, wearers can choose from a variety of crystal pavé designs in different patterns, sizes, and colors. The mix-and-match system lets users personalize their eyewear with shimmering crystal colors. Each pair becomes a reflection of individual style and creativity.

M’eye DIAMOND starter kit (code: MED101) is available to order.

Please Contact Us for the user manual for ES PRO 800M.